-

Bobcat T595 Rubber Track | 320x86x49

Vendor:TrackTECHRegular price From $847.06 USDRegular price$999.00 USDSale price From $847.06 USDSale -

Bobcat T650 Rubber Track | 400x86x52

Vendor:TrackTECHRegular price From $1,094.00 USDRegular price$1,199.00 USDSale price From $1,094.00 USDSale -

John Deere 319D Rubber Track | 320x86x52

Vendor:TrackTECHRegular price From $899.00 USDRegular price$1,009.00 USDSale price From $899.00 USDSale -

CAT 299D3 Rubber Track | 450x86x60

Vendor:TrackTECHRegular price From $1,299.00 USDRegular price$1,524.00 USDSale price From $1,299.00 USDSale -

John Deere 333G Rubber Track | 450x86x58

Vendor:TrackTECHRegular price From $1,289.00 USDRegular price$1,429.00 USDSale price From $1,289.00 USDSale

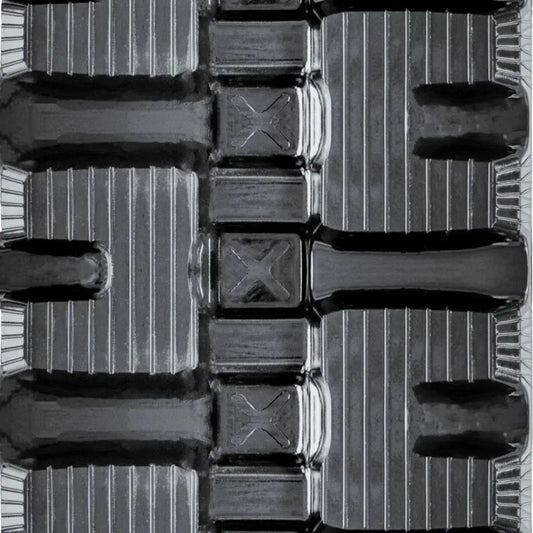

Heavy Duty Rubber Tracks for Skid Steers & Mini Excavators

Frequently Asked Questions

Everything you need to know about rubber tracks

How long do rubber tracks last?

With proper maintenance, rubber tracks typically last 1,500-2,000 hours. Heavy-duty tracks in ideal conditions can reach up to 5,000 hours. Factors affecting lifespan include terrain, operating conditions, and maintenance practices.

How do I know what size track I need?

Track sizes follow the format Width x Pitch x Lug Count (e.g., 450x86x55). You can find your current track size printed on the sidewall, check your machine's manual, or use our Track Finder tool to search by make and model.

What's the difference between track guide types?

Track guide types determine how the track fits your undercarriage:

- N/K Guide: Offset center guide, most common on CTLs

- W Guide: Wide center guide for heavy-duty applications

- B Guide: Block-style guide

- T Guide: Specific to Takeuchi machines

Using the wrong guide type will prevent proper installation.

Do you offer same-day shipping?

Yes! Orders placed before 12PM CT ship same day from our Georgia warehouse. Most locations receive delivery within 1-3 business days. Local pickup and delivery within 50 miles of Destin, FL is also available.

What warranty do TrackTECH tracks include?

All TrackTECH rubber tracks include a 24-month warranty covering manufacturing defects. Our tracks feature continuous steel cord construction, forged metal cores, and single-cure technology for maximum durability.

Tech Specs & Fitment Data

For Mechanics and Fleet Managers

| Specification | Heavy Duty for Skid Steers & Mini Excavators Standard | TrackTECH Enhanced |

|---|---|---|

| Cord Type | Overlap Joint (Prone to snap) | Continuous Steel Cord (No weak points) |

| Rubber Grade | Standard Black Carbon | Anti-Chunk Compound (50% more wear life) |

| Average Track Life | 1,200-1,500 operating hours | 1,800-2,200 hours (verified field data) |

| Warranty Coverage | 12 Months / 1,000 Hours | 24 Months / 1,500 Hours |

| Tread Options | Limited patterns | C-Lug, Multi-Lug, Z-Pattern available |

| Shipping Speed | 5-7 Business Days | Same Day (orders before 12PM CT from GA) |

⚠️ Mechanic's Advice

When replacing rubber tracks on Heavy Duty for Skid Steers & Mini Excavators machines, always inspect the drive sprocket for "shark fin" wear. Installing new tracks on worn sprockets voids the warranty and reduces track life by 40%. If your sprocket teeth are pointed instead of flat-topped, replace the sprocket before installing new tracks. This prevents premature tearing at the guide lugs and ensures optimal undercarriage performance.

Frequently Asked Questions

How long do Heavy Duty for Skid Steers & Mini Excavators rubber tracks last?

TrackTECH Heavy Duty for Skid Steers & Mini Excavators rubber tracks average 1,800-2,200 operating hours under normal working conditions. With proper maintenance—including tension checks every 50 hours and debris removal after muddy conditions—some contractors report up to 2,500 hours. Track life depends on terrain type, operator habits, sprocket condition, and whether you're running on asphalt versus dirt. Regular inspection of guide lugs and undercarriage alignment extends service life.

What's the difference between C-Lug and Multi-Lug tread patterns?

C-Lug (Block tread) provides maximum traction and stability on hard surfaces including asphalt, concrete, and compacted soil. Best applications: grading work, paving projects, demolition, and finish grading. Multi-Lug (Zig-Zag pattern) excels in soft terrain with self-cleaning channels that prevent mud buildup. Best applications: landscaping, excavation, wet conditions, and loose soil. For mixed job site conditions, C-Lug is typically the safer all-around choice with better sprocket engagement and longer wear life.

Do I need to replace both rubber tracks at the same time?

Yes, always replace both tracks together as a matched pair. Mismatched track wear causes uneven tension across the undercarriage, leading to premature failure, poor tracking, and increased wear on rollers and idlers. Even if one track appears serviceable, mixing old and new tracks reduces the new track's service life by 30-40% and creates serious safety issues on slopes or uneven terrain. Replace in pairs to maintain proper machine balance and maximize your investment.

Will these tracks fit my specific model year?

Track sizing remained consistent across most model years for Heavy Duty for Skid Steers & Mini Excavators machines, but there are exceptions. Always verify your current track dimensions (Width × Pitch × Links) before ordering. The fastest way to confirm fitment is to call our Georgia warehouse at (850) 816-7898 with your machine serial number. Our team provides 100% fitment confirmation and can cross-reference OEM part numbers to guarantee the exact size match.