Durable Heavy Duty Rubber Tracks for Skid Steers and Mini Excavators

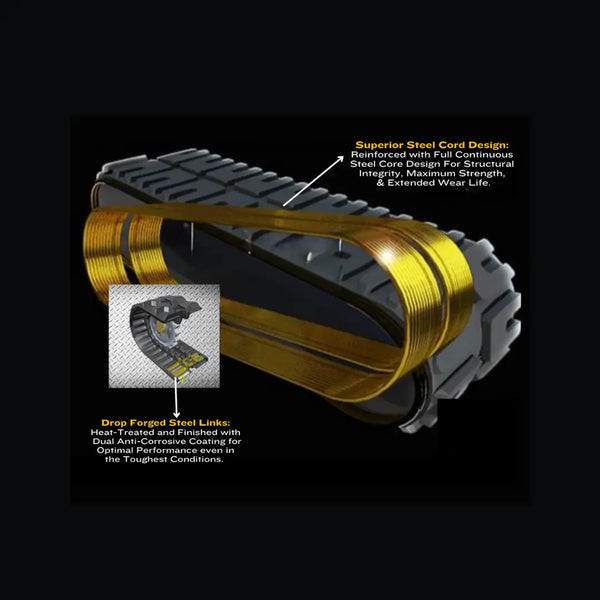

The TrackTECH HD Series is built for contractors who refuse to compromise. Featuring Continuous Steel Cord Technology and premium rubber compounds, these tracks are designed to resist cutting, chunking, and stretching on the toughest jobsites. Whether you are running a mini excavator or a high-flow skid steer, the HD Series delivers superior traction and extended service life. Verified fitment for all major makes and models. Don't let a broken track stop your progress—upgrade to the HD Series today.

Why Choose Heavy Duty Rubber Tracks?

Heavy duty rubber tracks offer an excellent balance of durability and performance. These tracks are specifically designed to withstand the rigors of tough job sites, ensuring that your skid steer or mini excavator operates smoothly. Unlike steel tracks, rubber tracks minimize ground damage and provide superior traction, making them essential for landscape, construction, and demolition work. They absorb shock effectively, which reduces wear and tear on your machinery, helping you perform jobs efficiently and safely.

Benefits of Using Rubber Tracks

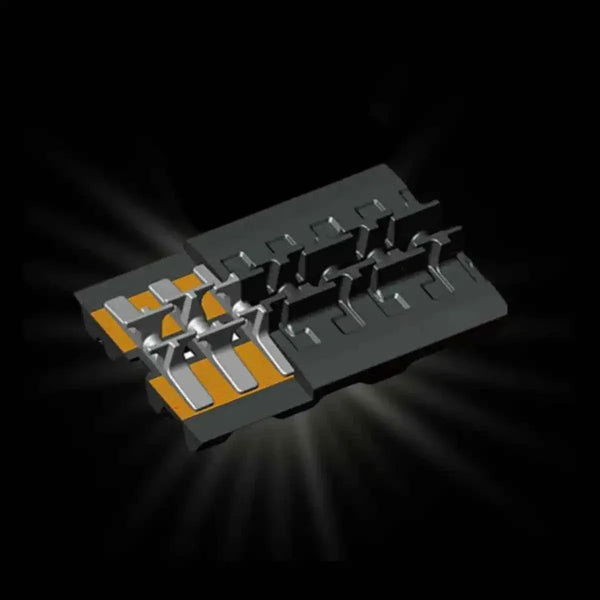

One of the main advantages of heavy duty rubber tracks is their versatility. They're suitable for various terrains, from muddy regions to rocky surfaces. Because rubber tracks have a larger surface area compared to conventional tires, they distribute weight evenly, which prevents sinking into soft ground. Additionally, they provide smooth operation, which is important for precision tasks. This adaptability makes them a popular choice among operators who face different working conditions regularly.

Choosing the Right Heavy Duty Rubber Tracks

When selecting heavy duty rubber tracks, it's crucial to consider the specifications of your machine. Make sure to measure the existing tracks and check the load capacity of your skid steer or mini excavator. Proper fit is essential to ensure optimal performance. You should also consider the tread pattern; for example, a more aggressive tread design may be ideal for muddy environments, while a smoother tread may be better on hard surfaces. Therefore, by understanding your specific needs, you can choose tracks that improve productivity and safety on the job.