Heavy-Duty Rubber Tracks for Multi-Terrain Loaders | All Brands

TrackTECH delivers contractor-grade MTL rubber tracks engineered for the demanding work multi-terrain loaders perform daily. From landscaping to demolition, our tracks provide the traction, durability, and flotation your machine needs to stay productive season after season.

We stock multi-terrain loader tracks for every major manufacturer including CAT, John Deere, and other manufacturers. Same-day shipping available on in-stock orders placed before 2pm Eastern, with free freight delivery to commercial addresses nationwide.

Built for MTL Performance

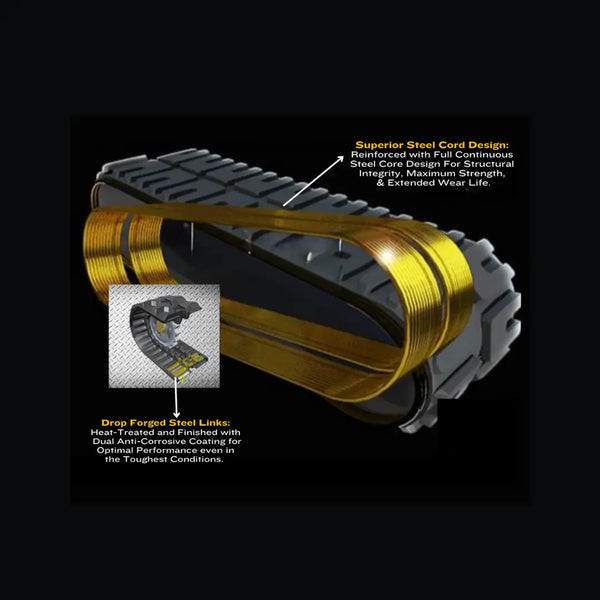

Every TrackTECH multi-terrain loader track features continuous steel cord construction—the same technology used in premium OEM tracks. Unlike overlapped cable designs found in economy tracks, our single-loop construction eliminates weak points where cables traditionally overlap. This means superior tensile strength, resistance to stretching, and longer service life under demanding conditions.

Our rubber compound uses 100% virgin material rather than recycled content. Virgin rubber delivers measurably better tear resistance, chunk resistance, and overall durability. Contractors consistently report 20-30% longer service life compared to tracks containing reclaimed materials.

The embedded steel cords run the full circumference without splices or joints. No predetermined failure points. No sudden track separation during operation. Just reliable performance hour after hour.

Common MTL Track Sizes

Most multi-terrain loaders use tracks in the 320x86, 400x86, and 450x86 size families. Within each family, link count varies based on specific machine models. Always verify your required size by checking the sidewall stamp on your current tracks—the molded numbers indicate width, pitch, and link count.

If the sidewall markings are worn or unclear, contact TrackTECH at 850-816-7898 with your machine model and serial number. Our fitment specialists maintain comprehensive databases covering current and legacy multi-terrain loader models from all major manufacturers.

Tread Pattern Selection

TrackTECH offers multi-terrain loader tracks in multiple tread configurations. Selecting the right pattern for your typical terrain significantly impacts traction, wear, and ride quality.

C-Block Pattern: Flat rectangular lugs optimized for hard surfaces. Excellent on concrete, asphalt, and packed gravel with minimal vibration. Preferred for finished sites and operators prioritizing ride quality.

Zig-Zag Pattern: Aggressive angled lugs with superior self-cleaning action. Essential for mud, soft soil, wet conditions, and excavation work where material shedding matters.

Multi-Bar Pattern: Versatile hybrid design for operators encountering varied conditions throughout the workday. Balanced performance without excelling in any single terrain type.

Proper Track Maintenance

Maximize multi-terrain loader track life through proper tensioning and regular inspection. Under-tensioned tracks accelerate wear on drive components. Over-tensioned tracks stress the carcass and reduce flexibility. Consult your operator's manual for model-specific tension specifications.

Inspect tracks regularly for missing or damaged lugs, exposed steel cords, cracks, and uneven wear patterns. Abnormal wear often indicates alignment or tension problems that will damage replacement tracks as well. Address these issues before installing new tracks.

For industry standards and equipment specifications, visit Association of Equipment Manufacturers.

Related Collections

Browse related categories: CTL Tracks • Skid Steer Tracks.

Warranty and Shipping

Every multi-terrain loader track includes TrackTECH's 24-month warranty covering manufacturing defects and premature failure under normal operating conditions. We ship via freight carrier with free delivery to commercial addresses in the continental United States.

Frequently Asked Questions

What brands of multi-terrain loader tracks does TrackTECH carry?

TrackTECH stocks multi-terrain loader rubber tracks for all major manufacturers including CAT, John Deere, and other manufacturers. We carry both current production sizes and legacy machine fitments.

How do I find the right multi-terrain loader track size?

Check the sidewall stamp on your current tracks for the size code showing width, pitch, and link count. If markings are unclear, contact TrackTECH at 850-816-7898 with your machine model and serial number for verification.

What tread pattern works best for multi-terrain loaders?

Choose C-Block for hard surfaces like concrete and asphalt. Select Zig-Zag for mud and soft soil. Multi-Bar offers balanced performance for varied terrain. Your typical operating conditions determine the optimal pattern.

Do multi-terrain loader tracks include a warranty?

Yes, all TrackTECH multi-terrain loader rubber tracks include an 24-month warranty covering manufacturing defects and premature failure under normal operating conditions.